ABOUT

One of the biggest problems we were facing in institute was water shortage. For a couple of weeks, we were falling short of water to even fulfil our basic needs of drinking water. Considering the fact that IIT Bombay is located in a coastal area with relative humidities of more than 70 %, which led us to believe that we could use this water, which we can term as a very important resource not put to use yet, to fulfill our daily needs.

Our motto is - Water, Wherever, Whenever

In India, cities are mostly dependent on tanker water whose quality is not verified by water purifiers. Moreover, there is a lack of water during summers in various parts of India. We have developed an atmospheric water generating technology will be able to provide pure drinking water 365 days a year.

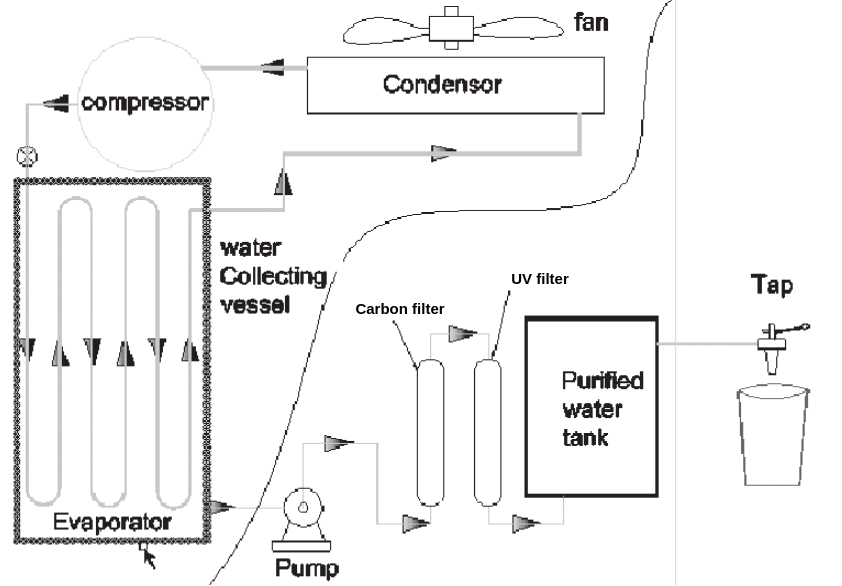

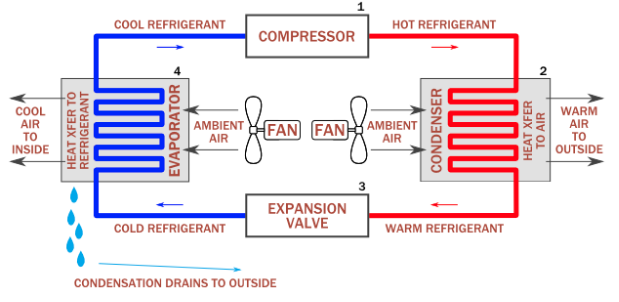

AquaGerator is a device that uses the basic principles of a refrigerator to generate fresh drinking water from the humidity in atmosphere and processing it through a series of purification methods. In this cooling condensation based atmospheric water generator, a compressor circulates refrigerant through a condenser and an evaporator coil which cools the air surrounding it, lowering the air’s dew point, and causing water to condense. A controlled speed fan pushes filtered air over a coil, the resulting water is then passed into a holding tank with purification and filtration system to keep the water pure by using UV and Carbon filters.

WORKING MECHANISM

The air compressor sucks in air and compresses it, raising its temperature. This hot air is transferred to the airtight evaporator coils via copper tubes which contains the cold coolant. The evaporator coil is a part of the refrigerant cycle. There will be heat exchange between the coolant and the hot air so that the temperature of the air falls below the dew point and thus air condenses. The hot coolant is then sent to the refrigerator compressor which compresses it and sends it to the condenser which cools it again. The condensed water is filtered using a carbon filter and a UV filter. Carbon filter settles physical impurities like particles, and UV filter kills the bacteria. The processed water is now available for use.

DESIGN

These are the images of the working prototype made by the team. It consists of an airtight container made out of wood covered in food grade plastic. The insides of wood are covered by thermocol sheets and aluminium foils. The compressor is placed on the top of the container, the condensor is attached to the back wall and the evaporator is latched onto the top face of container. An exhaust fan which works as air compressor is carved into the wood just above condensor such that it blows over the evaporator coils. The bottom part of container is made into a quadrilateral pyramid shape that has an outlet at the tip of the base and is covered with aluminium sheets for maximising water collection capacity. This container also has a small door to check the functionality from time to time.

Following is an overview of the design decisions made by us -- We had to cover wood with something so that it does not get wet. Our first alternative was to cover the whole inside of the container with aluminium, We tried to stick aluminum with wood but it didn't hold well. So, we decided to go with food grade plastic. All pieces of wood are individually wrapped with multiple layers of food grade plastic and joined together with MSeal. To prevent water to come in contact with mseal inside the container, we also wrapped the inside of the container with the plastic carefully.

- When we poured water in the container for testing, the water didn't come out smoothly. The water droplets stuck to the plastic as it had grooves that didn't let water to slide down. To overcome this, we covered the base with four triangular aluminium sheets with the help of araldite.

- For the outlet of water, we fixed the spout of the pipe around the hole at the bottom with araldite and mseal. It will be attached to a valve through a garden pipe which will be finally attached to the filters.

- We came across the fact that lid with the attached evaporator can’t be moved after the coolant is filled in the refrigeration cycle as any movement of evaporator could cause a leak in the cycle. We needed an opening to the container and hence decided to incorporate a door on the side wall, that is just opposite to the side having the condenser coil.

- The height of the container had to be increased to provide a better support to the condenser coil.

- Wood rots due to the contact of water, although covered with layers of plastic sheets there was a risk of water seeping through them to the wood. To tackle this we decided to stick thermocol sheets on the inner side of the walls and further cover it will aluminum foil and sealing the ends with duct-tape as the adhesive on it is least affected by water, unlike normal tape that loses its adhesivity in water. The tri-layer of wood,thermocol and aluminium would allow the least amount of heat follow and thus a better insulation from the surrounding leading to more efficient cooling.

- We used an exhaust fan instead of the air compressor as it facilitates the movement of air over the compressor coil. There was no longer the need of an air compressor.